Carbon NovoTeh

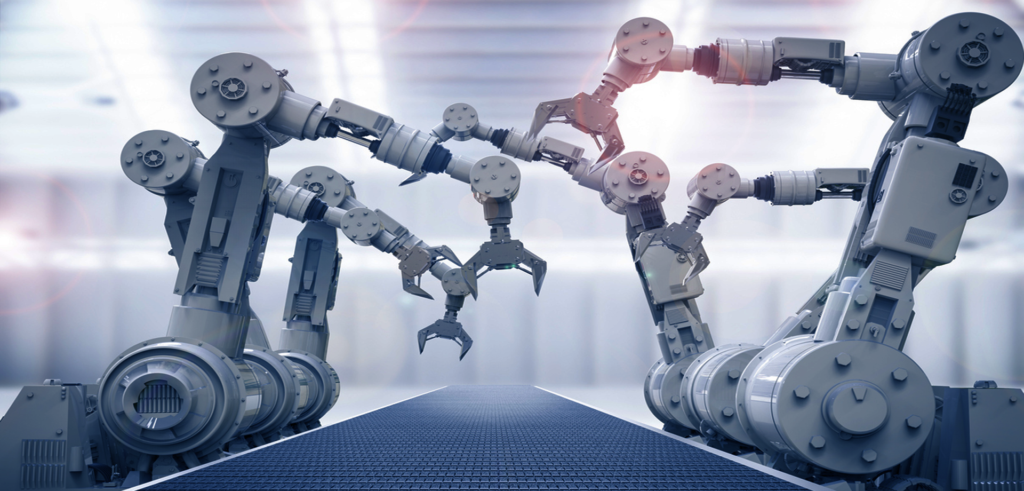

GUARANTEE FOR SOLUTIONS FACING THE FUTURE

Symbiosis of design, HW and SW development

Cross-platform development

Partnerships in industry and with universities

Mechanical engineering

Chemical engineering

Electrical engineering

Product

About us

Engineers with expertise from various disciplines of electrical engineering, informatics as well as mechanical and chemical engineering create the “all round” Carbon NovoTeh team. The team’s philosophy is based on discipline and work psychology combined with the effective use of our human resources. This allows us to find a suitable solution for every challenge of the modern IT era – Internet of Things, Industry 4.0.

The young, talented and highly motivated Carbon NovoTeh team is supported by the broad technical know-how of our internationally recognized partners. This guarantees continuous quality development and adherence to international norms and standards.

Our focus is on the client and his problems, concerns, ideas and wishes. Our mission is to fulfill your requirements and to find an optimal and transparent solution for your problems – this is what characterizes Carbon NovoTeh.

Due to the fact that trust is the basis for any successful and long-term cooperation, we attach the greatest importance to the security and protection of your intellectual property and information. We believe that a fair relationship between partners is essential, and if the partners’ experiences complement each other, then the foundations for long-term and successful cooperation have been created.

Our vision is to achieve perfection in our solutions and products using our own research and development.

What do we do?

Electrical Engineering

Development of embedded systems Software and application development PCB board design

Mechanical engineering

• Construction and design

• Mechatronics

• Solid Edge

• Catia

• Solidworks

• FEM – finite element simulation

FPGA

• Altera

• Xilinx

• Actel

• Catia

Safety engineering

• Creation of test specifications and implementation of tests in accordance with IEC 61508 & IEC 61131-3

• Support during the certification process

• Reliability analysis

• Analysis and design of programs and functional blocks according to IEC 61131-3

Chemical engineering

Chemical engineering implies

• chemical control

• fluid management processes

• development of technologies for galvanic processes

• on-site solutions

Products

• System of purification and disposal of waste water polluted by heavy metals

Carbon NovoTeh Product

DeTox 2708

The chemical engineering sector has developed a product that enables the replacement of classical methods of precipitation of heavy metals from aqueous solutions. This product does the adsorption of heavy metals in the range from pH=2 to pH=9, the factory name is DeTox 2708. By using this product, costs are reduced, the process is accelerated, residual sediment is easier to manage, the product is completely harmless. Its application is possible on already existing plants, but due to cost optimization, the benefit of individual application is multiple. The residue after purification is not voluminous and can very easily be deposited or modified and adapted for reuse for other purposes.

A module has also been developed that basically uses DeTox 2708, the module can be installed in any plant in the metal industry, in the metal surface protection industry.

Category: tertiary treatment.

- Purpose: industry, waste water recycling, removal of heavy metals, electroplating

- Flow: from 0.5 m 3 / h to 5 m 3 / h standard options and more than 10 m 3 / h according to the request.

- Material: HDPE, PPR, PVC

- High efficiency treatment

Adsorption technology is based on a product that has the ability to collect heavy metals on its surface. Heavy metal particles, as well as some nitrogen and sulfur compounds are removed from the water that passes through the filtration material. There are two main types of modules that are defined by the way they are installed: static and mobile.

The effectiveness of the filtration mechanisms depends on the characteristics of the water being treated, with which metal the water is saturated.

Job description

The flow of the process goes from receiving tanks, then tanks with mixers where, under automatic control, mixing, dosing of DeTox 2708, transfer to the sedimentation tank and then further through the sediment and water separation segment is carried out into the recipient.

The main parameters for determining the nominal values are: operational flow (m3 per day or lu seconds), and the type and concentration of pollutants (depending on the water analysis).

The modules usually operate with a constant flow, so the equalization reservoir is always installed beforehand to avoid peak flows.

The average flow rate is calculated based on effective working hours, maintenance plan and regeneration cycle (flushing). After the module, an accumulation tank is required, especially in devices for water recycling or industrial wastewater treatment to equalize the output flow and homogenize.

Handling and maintenance e

Handling and maintenance is prescribed for each segment of the module. Instructions for use with safety and other regulations have been prepared. After the saturation of DeTox 2708, which is read on the PLC, it is deposited, dried and stored in precisely specified containers.

Valves, PVC, pipes, pumps, etc. require periodic control and maintenance.

The by-pass system is designed for emergency maintenance and breakdowns.

Advantages and disadvantages

The modular system for the processing of municipal and industrial waste water is intended for plants where it is necessary to remove heavy metals. Modules are usually installed after clarification, flocculation or physico-chemical devices.

Pathogens are not removed during the procedure, so an additional unit for sterilization is often required, especially when recycling water.

Modules can work manually as well as automatically. Automatic control and monitoring is usually done using a programmable logic controller (PLC) and a microprocessor in combination with a parameter meter.

Advantages

- easy to install;

- simple maintenance plan;

- automated process (electromagnetic valves, PLC, processors);

- high removal efficiency;

- reliable technology.

- reduced amount of sediment

- reduced consumption of chemicals

Disadvantages

- maintenance by professional staff;

- required chemical analysis to select a technological process

- disposal of replaced material;

- required storage for load distribution/equalization.

Contact

Address:

office-18, Floor-31

High sky express business center , API World Tower

Sheikh zayed road

Dubai, UAE

E-mail:

Info@carbonnovoteh.com

Working hours:

Monday - Friday 00:00 - 00:00

Saturday 00:00 - 00:00